POTASSIUM METHYL SILICONATE IMPREGNATOR

→ See performance of WARRIOR W-40 IMPREGNATOR on YouTube

USES

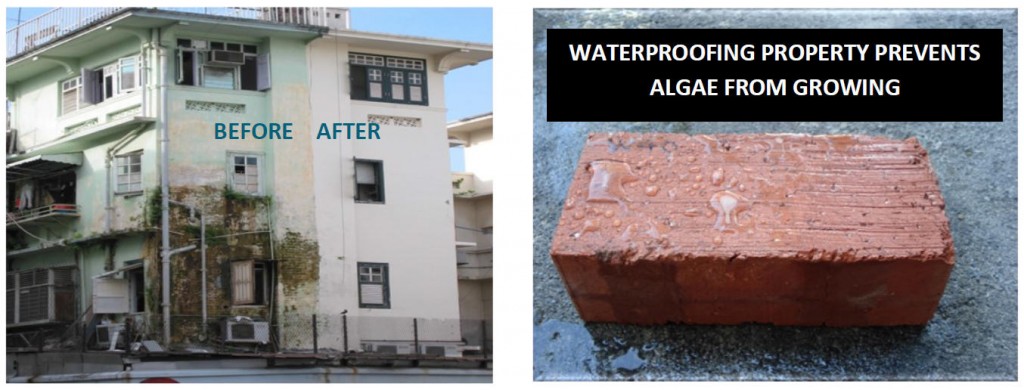

- To reduce water absorption and prevent algae growth, to enhance the self-cleaning effect to the treated surface.

- For plastered wall, concrete wall, ledge and roof, manufactured and white colour natural stones and aerated cement block before painting.

- To treat the back of stone to prevent rising dampness and salt penetration.

- To inject into building bored holes combating capillary rising damp in masonry.

- Low fired clay products e.g., roof tiles, bricks, aerated cement block and flowerpots.

- Gypsum & gypsum-based plaster board. Light fillers, such as perlite, vermiculites insulating material.

- To increase water resistance of paint material.

APPLICATION METHODS

External brick or concrete wall protection

- Concrete shall be allowed to cure for 28 days before application.

- The surface to be treated must be clean and sound. Allow the substrate to dry for 24 hours.

- Dilute W40 with 10 times of water, and brush onto the wall.

- Protect the treated surface from rainwater for 24 hours.

Remark:

For application on painted surface, always do a patch test before full application, to check the colour stability.

Warrior W-4 Water Repellent is recommended for application over tiles and paints where colour stability is prioritised.

W40 is highly alkaline. Avoid direct contact with skin and eyes during application.

Do not apply W40 on non-absorbent surface (such as glass and aluminium) or surfaces that have already been treated with water repellent. W40 residue might give rise to white spot if left to dry on surface.

For reducing of water absorbency of low fired clay products, such as bricks, roof tiles and flower pots

- Pre-dilute W40 with 50 times of water.

- Dip the products into the solution for 5 ~ 60 seconds, depending on the absorbency of the materials.

- Do not stack the materials immediately after the impregnation process.

W40 can also be added into surface paint (3% by weight) to increase its water resistance.

TECHNICAL DATA

Appearance Clear to Hazy liquid

pH 13 – Highly Alkaline.

SAFETY

- CORROSIVE & IRRITANT: W40 is strongly alkaline, due to the presence of POTASSIUM HYDROXIDE. Appropriate safety measures must be taken while handling the product; Protective glasses and gloves should be worn while using the product. Any splashes on the skin should be washed off with plenty of water.

- Spraying should be done with an airless spray. While spraying, the solution should not be atomized and inhalation of the spray mist should be avoided.

- To protect third party from contact with the alkaline fluid, the working area should be screened off from public during treatment.

- Allow excess W40 to be absorbed into the concrete and complete the chemical reaction, to avoid disposal.

PACKING

5 kg-carboy / 20 kg-jerry can

DOWNLOAD CATALOGUE in PDF (Right Click–Save As)