ELASTIC WATERPROOFING CEMENT ADMIX.

A WATER-BASED POLYMER DESIGNED TO MODIFY CEMENT

USES

- Flexible Waterproofing Cement: Toilet, Wet area, Basement, Diaphragm wall, Swimming pool, Fishpond, Flower trough.

- Tiles bonding – for laying tiles on flexing surfaces and to waterproof.

- Injection polymer and bonding aid for PVC to Paper

FEATURES

After mixing with White or Grey Cement compound.

- Bonding – excellent bonding property, will bond onto cement, sand, polyurethane, and bitumen surfaces. Therefore it can be coated over existing waterproofing membrane layer.

- Flexibility – Cured coating is elastic, flexible, and very stretchable with excellent contour conform-ing ability.

- Weathering – It is a chemically stable product, resists UV ageing, temperature changes, and re-mains impermeable to water.

- Withstands wide temperature changes – does not blister or soften at higher temperature; remains supple and flexible at lower temperature.

- Chemical resistance – resistance to mild acid and alkaline solution.

- Tough and resilient – suitable for various type of waterproofing needs.

- Environmentally friendly – It does not contain organic solvent, does not pollute, flame resistance, safe to use.

APPLICATION METHODS

Mix Ratio: W2 + Tile Bond Cement

20 % + 100 % by Weight

Usage: W2 = 1.2 kg / sq. m per 3 mm thick.

Allow 24 hours for curing before water testing.

- Ensure surface to be treated is clean and intact, Free of fine dust and oil.

- Hard brush applies W2 + Cement + Sand Slurry in 2 coats after the previous coat has dry. Final dry thickness is 1.5 to 2 mm.

- During application, the slurry should be mix well without seeing the polymer floating above.

- It can be applied over damped surface.

Waterproofing Membrane:

- Mix & stir to ensure uniform distribution.

- Increasing amount of cement during mixture will increase hardness.

- If finer calcium carbonate is used in dry powder mixture, it will be more viscous.

- With higher content of W2 the elongation rate at break, cohesion and water resistance will in-crease.

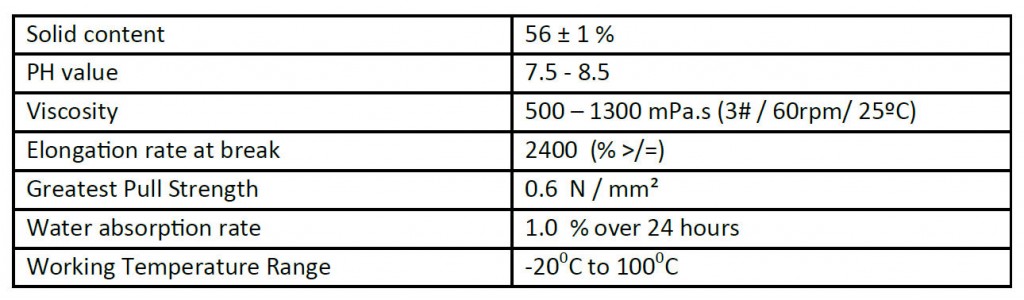

TECHNICAL DATA

PSB Test: Jan 31, 2002 DIN 1048 Part 5: 1991 Zero water penetration on concrete

PACKING

5 litre-carboy, 20 litre-jerry can

DOWNLOAD CATALOGUE in PDF (Right Click–Save As)